N.B. This page is modified every now and then.

.

The AIDA project is a PhD-project of Ir. D.W.E. Rentema. Closely involved are Prof.ir. E. Torenbeek, Prof.dr.ir. F.W. Jansen and Dr.ir. R.A. Vingerhoeds. They represent three groups within the Delft University of Technology:

top

top

AIDA is a tool which supports the designer in the first phase of the aircraft design process: the conceptual design phase. There are already many design support tools available, but they are focused on the following design phases, which are numerical oriented. ADAS (Bil, 1988) is such a tool, developed at the Faculty of Aerospace Engineering of Delft University of Technology. It supports the preliminary design of aircraft by optimising the concept of an aircraft and adding details.

The support tool described in this paper focuses on the conceptual design phase, which requires more creativity and qualitative reasoning. Artificial Intelligence (AI) techniques are applied to the more qualitative aspects of the conceptual design. The project is therefore called AIDA: Artificial Intelligence supported Design of Aircraft. With the assistance of AIDA the designer should be able to give more attention to the creative issues, than spending much of his time on keeping track of the design process and managing software tools.

Within the conceptual design process several tasks can be distinguished. To perform these tasks, various AI-techniques are implemented in the AIDA project, like Constraint-Based Reasoning, Case-Based Reasoning and Rule-Based Reasoning. The intention is that the general concept of AIDA can also be used in other domains, like ship or car design.

The aircraft design process can be divided into several phases. The design process is started with the formulation of the design specifications, for which the concept is specified. This includes the determination of the lay-out of the aircraft, and the approximation of some of its primary parameters. This is the domain of AIDA. In the successive design phases more details are added and estimations of parameters are improved.

Based on the work of Torenbeek (1982), some sub-goals can be distinguished which appear in almost every (civil) aircraft conceptual design phase. For example, the creation of a loading diagram, which is used to approximate the wing area and engine thrust or power. In the diagram the performance specifications are represented. To be able to represent these specifications, more information about the design object (the aircraft) is required. This forces the designer to make decisions about the lay-out and some other parameters. So, the design process is directed by a pattern of sub-goals and by the relations which are used to arrive at those sub-goals. Most of the relations are heuristically described, based on statistics and simplified physics. The decisions are initially taken using qualitative and highly speculative arguments, which are based on experience of the designers themselves or implicitly in previous designs (existing aircraft and statistics).

The purpose of AIDA is to support the reasoning involved in arranging the lay-out and the generation of feasible functional (like the performance) and geometrical parameters. AIDA will also supply the first quantification of parameters as a starting point for further numerical optimisation.

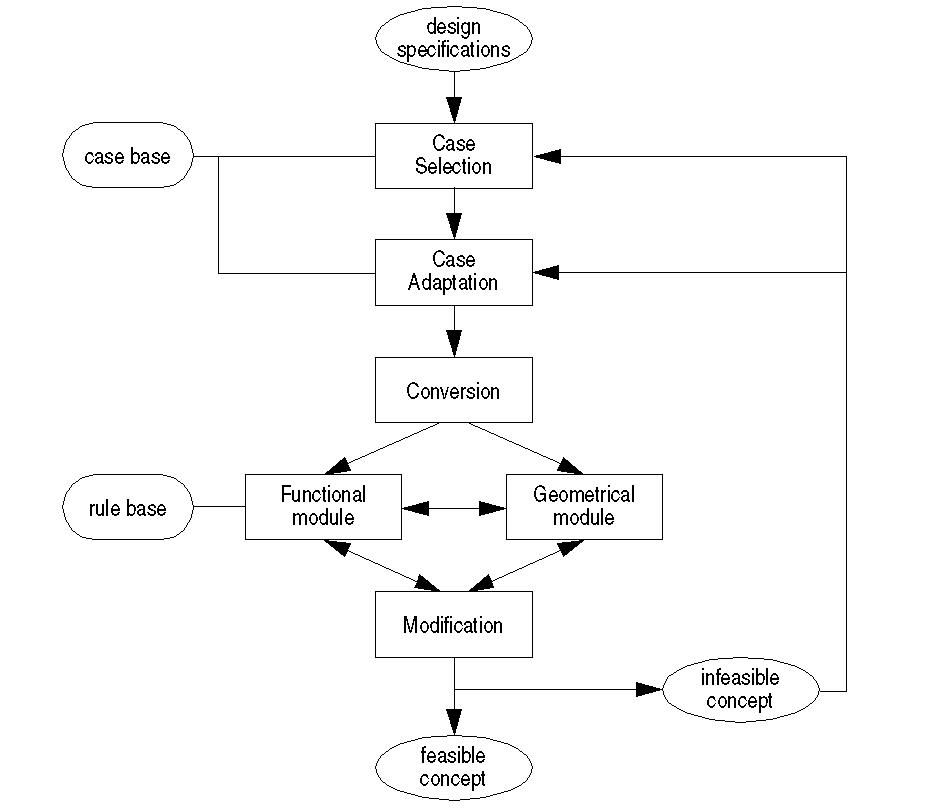

The AIDA system will consist of a number of modules, each performing a different design task. For each task one or more reasoning technique are implemented. These include AI-techniques like Rule-, Case- and Constraint-Based Reasoning, and geometrical reasoning. In next figure the set-up of AIDA is sketched.

The Case Selection module applies Case-Based Reasoning to suggest initial values and lay-out choices, using the experience which is implicitly stored in existing cases. The suggestions are based on similarities with the problem specifications. The best matching case will, in general, not completely meet the specifications. Therefore, a first adaptation of the case is performed with the aid of the case base, using the deficient parameters to guide the adaptation process.

The information in the adapted case will be used as a starting point for the remainder of the process. The Conversion module translates this information into the appropriate geometrical information for the Geometrical module and into the appropriate knowledge for the Functional module.

The Functional module provides links between functional and geometrical parameters. It creates a network of relations, based on the problem specifications and the primary parameters. The network is created using Rule-Based Reasoning techniques, and will be utilised to quantify parameters and to perform parameter studies. The data of the adapted case is used to select the relevant relations and to supply initial parameter values. The Functional module will provide parameter values for the Geometrical module, and will receive typical geometrical data from the Geometrical module.

The Geometrical module creates a parameterised solid model of the design object. This model is used to give the designer visual feedback and to check for geometrical constraints. Also typical geometrical information can be deduced, like volumes and the locations of centres of gravity.

When functional and/or geometrical constraints have been violated, the parameter values have to be modified. General suggestions for the modifications can be formalised by rules. When the suggestions are too complex, parameter studies are carried out to reveal the influence of certain parameters; this can be performed using the network as created by the Functional module. When these modifications are not sufficient to meet the design specifications, another lay-out has to be chosen. This will require the retrieval of another case with a different lay-out or another adaptation of the case. In that case the conceptual design process starts all over again.

Some related projects have been finished, of which the results will be used for AIDA. Netten (1997, 1993) developed a conceptual design tool for fibre reinforced composite structures (EADOCS), using a combination of Constraint-Based Reasoning, Case-Based Reasoning and Rule-Based Reasoning. This tool can be applied for the Case selection and Case adaptation. Van Hees (1997) developed an expert governed system for the assembly, execution and maintenance of parametric design models of ships (QUAESTOR). It applies a Rule-Based structure and some numerical optimisation and interpolation routines. This system will be used for the Functional module.

Current work is focused on the Conversion and Geometrical module, and on the acquisition of the domain knowledge for the implementation in EADOCS and QUAESTOR.

top

top

top

top

top

top

Contact adress: Date Rentema

|

Delft University of Technology Faculty of Aeronautics Group of Aircraft Design Kluyverweg 1 2600 GB Delft The Netherlands tel.: (+3115) 278 53 33 fax.: (+3115) 278 34 44 |

or |

Delft University of Technology Faculty of Technical Mathematics and Informatics Group of Knowledge Based Systems Zuidplantsoen 4 2628 BZ Delft The Netherlands tel.: (+3115) 278 53 33 / 10 31 fax.: (+3115) 278 71 41 |

| e-mail: d.w.e.rentema@cs.tudelft.nl |